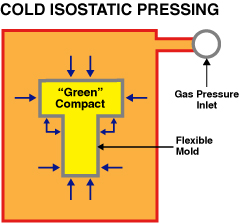

Cold Isostatic Pressing

Cold isostatic pressing has the advantage for producing parts where the high initial cost of pressing dies cannot be justified or when very large or complex compacts are needed. A variety of powders can be pressed isostatically on a commercial scale, including metals, ceramics, plastics, and composites. Pressures required for compacting range from less than 5,000 psi to more than 100,000 psi (34.5 to 690 MPa). Powders are compacted in elastomeric molds in either a wet or dry bag process.